|

INTRODUCTIONS |

|

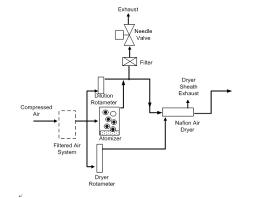

This economical aerosol generation system is designed to generate testing aerosols for various applications, such as calibration of laser particle counter. This aerosol generation system can polydisperse particles from 0.1 to 10 micrometers in diameter. Generation of the particles of interest starts with atomization of a dilute suspension of the particles in de-ionized (DI) water. The suspension, containing particles such as PSL spheres, salt, etc…, is placed in the atomizer reservoir. Dry, filtered, compressed air is used to atomize the mixture to form a droplet fog, which is then passed through a Nafion membrane air dryer, resulting in evaporation of water and production of dry aerosol. The dry aerosol stream is then introduced to the laser particle counter. The whole system will be mounted on a 24" x 30" plate for convenient transport. |

|

MAJOR COMPONENT: |

|

1.Filtered Air Supply System (FASS) |

|

2. Single Jet Atomizer (7388SJA) The sub-micrometer atomizer is designed for nebulizing a liquid solution or suspensions. The atomizer produces liquid droplets which have mean droplet size of 3.0 μm and a standard deviation of less than 2.0. The atomizer is ideal for generating liquid or solid aerosols from wide rang of solutions or suspensions, including polystyrene latex (PSL) spheres, dioctyl phthalate (DOP) salt or sugar solutions. The atomizer is widely used to aerosolize NIST's Standard Reference Materials (SRM). The aerosol output is approximately 4.5 L/min (with input pressure of 35 psi or 241 Kilopascal). |

|

Aerosol Generation System(7388AGS ) |

|

What's included in the 7388AGS? • Filtered Air Supply System (FASS) • 3-Jet Collision Atomizer (CN-24) • Nafion Air Dryer • nterconnecting hardware, including flow meters (03217-26),valve (06394-07), HEPA filters (9933-11-BQ-1), connectors and tubing, etc…

Specifications (Subject to change without notice) • Particle material: Solid or nonvolatile liquid • Particle size range: 0.1μm to 10μm • Particle concentration: 0 to 107 particles/cm3 • Aerosol flow rate: 0.1 to 30 lpm • Note: User needs to supply clean compressed air, testing aerosols and de-ionized water |

|

Specifications: Flow rate (maximum): 100L/min Inlet air pressure (maximum): 1000kPa (150psig) Pressure regulator: 0 to 415kPa (0 to 60psig) Pressure gauge: 0 to 415kPa (0 to 60psig) Dryer type: membrane dryer BX and final filters: 99.99995% for 0.1μm DOP at a face velocity of 10cm/s |

|

3.Nafion Membrane Air Dryer The Nafion membrane air dryer remove moistures from sample aerosols. This air dryer transfers moisture from one gas stream to a counterflowing purge gas stream, much like a shell-andtube heat exchanger transfers heat. Water molecules permeate through the Nafion tube wall, evaporating into the purge gas stream. No more drying of desiccant materials. |

|

Specifications: • Dryer type: membrane dryer • Air flow rate: 0 to 4 L/min • Nafion Tube OD/ID: 0.072"/0.060" • Available Length: 12" • Outlet RH: 10% at flow rate of 0.2 L/min, 45% at flow rate of 4.0 L/min |