|

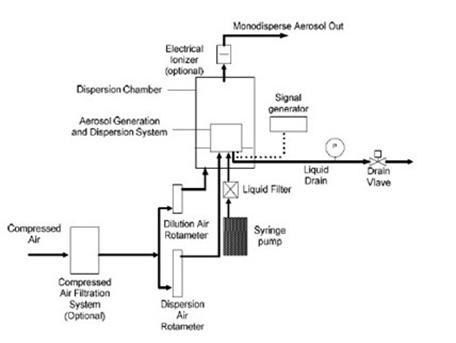

The Model 7388VOG is based on the breakup of a liquid jet to generate narrow size distribution of aerosol particles of selected size. The generation of particles starts with injecting dilute suspension of the particles (i.e., nonvolatile solute) in a volatile solvent (e.g., Isopropanol) to the aerosol generator. The liquid suspension, containing particles such as DOP, salt, etc…, is placed in a syringe and is delivered to the aerosol generator by a syringe pump. The liquid flow rate is controlled by the syringe pump. As the liquid passes through the orifice inside the aerosol generator, a fine liquid jet is produced which tends to break up into droplets. By applying a periodic disturbance of appropriate frequency to the jet, the breakup process can be controlled to produce uniform droplets. These droplets are dispersed and diluted with clean air. The dispersion air helps to prevent significant coagulation and the dilution air helps to dry the dispersed droplets. The monodisperse aerosol is then produced using the solvent evaporation technique. The diameter of the final aerosol particle can be varied by changing the concentration of the nonvolatile solute in the solution. As the generated particles from the VOG are highly charged, it is recommended that the generated particles are introduced to an electrical ionizer (order separately), where particles are brought to a Bolzmann charge distribution by the high concentration of negative and positive ions. The neutralized monodisperse particles are then coming out from the VOG. The Model 7388VOG allows the user to generate high-quality monodisperse aerosols that can be used for a variety of practical applications such as: • Instrument calibration • Instrument size and material responses study • Fundamental aerosol research |

|

7388VOG Vibrating Orifrice Generator |

|

7388VOG的振动孔板发生器的示意图 |

|

Major Components: 1. Aerosol generation and dispersion system The aerosol generation and dispersion system is the key component of the Model 7388VOG. Its main function is to disperse the liquid into uniform droplets and to generate aerosols. It consists of

|

|

Aerosol Generation and Dispersion System |

|

Air flow control system |

|

2. Air flow control system The air flow control system is a component of the Model 7388VOG to control the air flows in the system. It controls the dispersion air flow and the dilution air flow. |

|

3. Liquid supply system The liquid supply system of the Model 7388VOG is used to supply liquid solution to the aerosol generation and dispersion system. The main component of the liquid supply system is the syringe pump. It also consists a drain valve to drain liquid when the aerosol is not producing. It also consists a pressure gauge to monitor the liquid pressure in the system. |

|

Liquid Supply System |

|

4. Signal generator The major function of the signal generator (Figure 5-5) is to supply Sine wave voltage signal to the piezoelectric ceramic head that makes the orifice disk oscillate. The frequency of the signal generator can be adjusted between 0.2 Hz to 20 MHz. The voltage signal altitude is preset to ~ 7V. |

|

Signal Generator |

|

Specifications: |

|

INTRODUCTIONS |

|

Schematic Diagram of the Model 7388VOG Vibrating Orifice Generator |

|

- Orifice disc - Piezoelectric ceramic head - Liquid chamber and base - Dispersion cap - Liquid feed and drain tubes - Electrical spring connector - Dispersion air tubes - Dilution air screen |

|

Mode of operation |

Constant liquid feed rate through a vibrating orifice. |

|

Particle size range |

1-40μm standard; up to 200μm with optional large orifices. |

|

Particle type |

Oil, solids soluble in water and alcohol * |

|

Syringe Pump Spec or similar ( syringe pump included) |

|

|

Syringe ram speed |

0.1 x 10 –4 to 9.9 x 10 –3 cm/sec |

|

Flowrate |

Selectable 0.001 cm3 (10 cm3 syringe) to 3.3 cm3/min (60 cm3 syringe) |

|

Syringe holder |

Holds 10, 20, 60 cm3 syringes |

|

Signal Generator included (this is externally spacing, not internally in the generator) Frequency range: 0.2 Hz to 20 MHz Accuracy: Time base ±1 count Output voltage: 20V (open circuit), 10V (into 50Ω load) |

|

|

Orifice material |

Stainless steel |

|

Drying column material |

Acrylic or glass upon client requested |

|

Environmental conditions |

Indoor use Ambient temperature range 10-37℃ Ambient humidity 0-90% RH noncondensing |

|

Electrical requirements |

230VAC 50-60 Hz, single phase |

|

Fuse |

230/240V ~ T .5A/230V |

|

Compressed air requirements |

Up to 100L/min at 207 kPa (30 psi) |