|

INTRODUCTIONS |

|

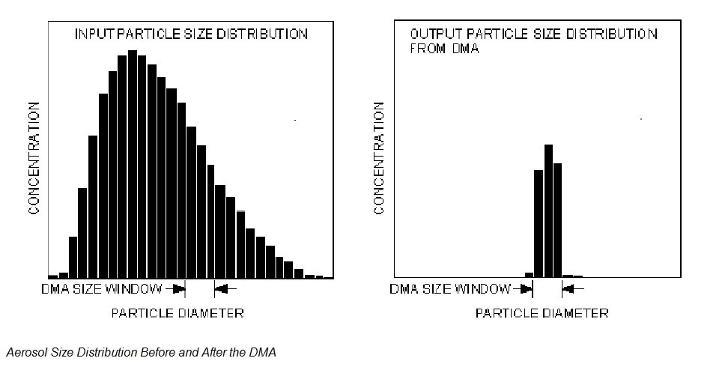

This aerosol generation system generates monodisperse sub-micrometer particles from 0.01 to 1.0 micrometers in diameter. Generation of the particles of interest starts with atomization of a dilute suspension of the particles in deionized (DI) water. The suspension, containing particles such as PSL spheres, salt, etc…, is placed in a stainless steel atomizer reservoir. Dry, filtered, compressed air is used to atomize the mixture to form a droplet fog, which is then passed through a Nafion membrane air dryer, resulting in evaporation of the water and production of dry aerosol. The dry aerosol stream enters a differential mobility analyzer (DMA) to remove particles of unwanted size, resulting in an aerosol consisting of uniformly sized (monodisperse) particles. |

|

7388SMAG Includes: |

|

1.Filtered Air Supply (CAFS) |

|

2.Sub-micrometer Single Jet Atomizer (SJA) The sub-micrometer atomizer is designed for nebulizing a liquid solution or suspensions. The atomizer produces liquid droplets which have mean droplet size of 3.0 μm and a standard deviation of less than 2.0. The atomizer is ideal for generating liquid or solid aerosols from wide rang of solutions or suspensions, including polystyrene latex (PSL) spheres, dioctyl phthalate (DOP) salt or sugar solutions. The atomizer is widely used to aerosolize NIST's Standard Reference Materials (SRM). The aerosol output is approximately 4.5 L/min (with input pressure of 35 psi or 241 Kilopascal). |

|

3.Nafion Membrane Air Dryer The Nafion membrane air dryer remove moistures from sample aerosols. This air dryer transfers moisture from one gas stream to a counterflowing purge gas stream, much like a shell-andtube heat exchanger transfers heat. Water molecules permeate through the Nafion tube wall, evaporating into the purge gas stream. No more drying of desiccant materials. |

|

4.Inlet Impactor The inlet impactor removes supermicrometer particles from the sample stream. Total of three different nozzle sizes are supplied with the impactor to enable wide range of cut size diameters. |

|

5.Electrical Ionizer Prior entering the differential mobility analyzer (DMA), particles generated by the atomizer should be directed to an electrical ionizer where the particles are brought to a Boltzmann charge distribution by the high concentration of air ions generated by the electrical ionizer. This minimizes particle losses in transport and provides a known particle charge distribution for size analysis by differential mobility analyzer. |

|

6.Differential Mobility Analyzer (DMA) The differential mobility analyzer (DMA) capable of classifying particles in the size range from 10 to 1000 nm. This classification is accomplished by passing particles through a well-defined electric field. Only particles with a specific electrical mobility penetrate the DMA exit slit. The mean size of the particles that penetrate the DMA is a function of the flow rates and of the strength of the electric field. All other particles are collected on surfaces inside the DMA or leave with the excess flow depending upon their sizes. The transfer function of each DMA is measured experimentally in the laboratory to ensure optimum DMA performance. |

|

The DMA is of cylindrical design with a total height of approx. 89 cm. The DMA works in the recirculating mode, where the sheath air flow is in a closed loop with a steady flow that is accurately controlled by a feedback control system. The DMA sheath air flows are filtered upstream and downstream of the recirculating pump with highefficiency (>99.99%) filters to ensure particle-free sheath air. The absolute pressure and temperature of the sheath air flow are also measured and used by the system to improve the accuracy of the particle electrical mobility and diameter calculations. |

|

7.Control System The monodisperse aerosol generation hardware system is controlled with proprietary software executed by a single-board computer operating on the Windows® XP operation system platform. The computer has an LCD display, a hard drive (e.g. 80 GB or higher), a serial communications card and a mouse. The internal computer along with a programmable logic controller (PLC) are used to communicate with and control system devices in the monodisperse aerosol generation system. The PLC is used primarily for analog I/O and digital I/O. The computer interfaces with the PLC using one Ethernet port. Control functions include operating flow controller, monitoring flow rates, pressures, temperature, and setting and monitoring high voltage levels.

|

|

8.DC Power Supplies One low-voltage switching power supply and one high-voltage DC power supply provide all the power required by the system. The low-voltage power supply has several DC output voltages (i.e. +12 VDC, +5VDC, -12VDC, -5 VDC) that supply power to the different circuit boards of the system. The high voltage power supply generates the DMA operating voltage that can vary from 10 VDC to 10,000 VDC. This power supply has two output voltage monitors, one for the low voltage range (0 to 1000 VDC) and the other for the high voltage range (1,000 to 10,000 VDC).

|

|

Specifications (Subject to change without notice) Particle material: Solid or nonvolatile liquid Particle size range: 10 nm to 1000 nm Particle concentration: ~ 0 to 106 particles/cm3 Aerosol flow rate: 0.1 to 1 lpm Monodispersity: GSD <= 1.05 |

|

7388SMAG Sub-micrometer Aerosol Generation System |

|

Specifications: • Flow rate (maximum): 100L/min • Inlet air pressure (maximum): 1000kPa (150psig) • Pressure regulator: 0 to 415kPa (0 to 60psig) • Pressure gauge: 0 to 415kPa (0 to 60psig) • Dryer type: membrane dryer • BX and final filters: 99.99995% for 0.1μm DOP at a face velocity of 10cm/s |

|

Specifications: • Dryer type: membrane dryer • Air flow rate: 0 to 4 L/min • Nafion Tube OD/ID: 0.072"/0.060" • Available Length: 12" • Outlet RH: 10% at flow rate of 0.2 L/min, 45% at flow rate of 4.0 L/min |

|

What's included in the SMAG? • Filtered Air Supply System • Stainless Steel Single Jet Atomizer (SJA) • Nafion Air Dryer • Inlet Impactor • Electrical Ionizer • Differential Mobility Analyzer (Long Style) • DMA re-circulating pump • High voltage power supply for DMA • Control system with a single board PC and a PLC • Interconnecting hardware, including valves, filters and tubing, etc… |